Industrial fermentation plants are harsh, hard-driving environments that require heavy duty machinery, complex duct work, and robust safety protocols to handle dangerous and toxic substances. They offer jobs with higher than average compensation to offset the long shifts in sweltering heat, deafening noise, and noxious fumes wafting throughout labyrinthine tunnels. Recruiting and retaining staff is a perennial task.

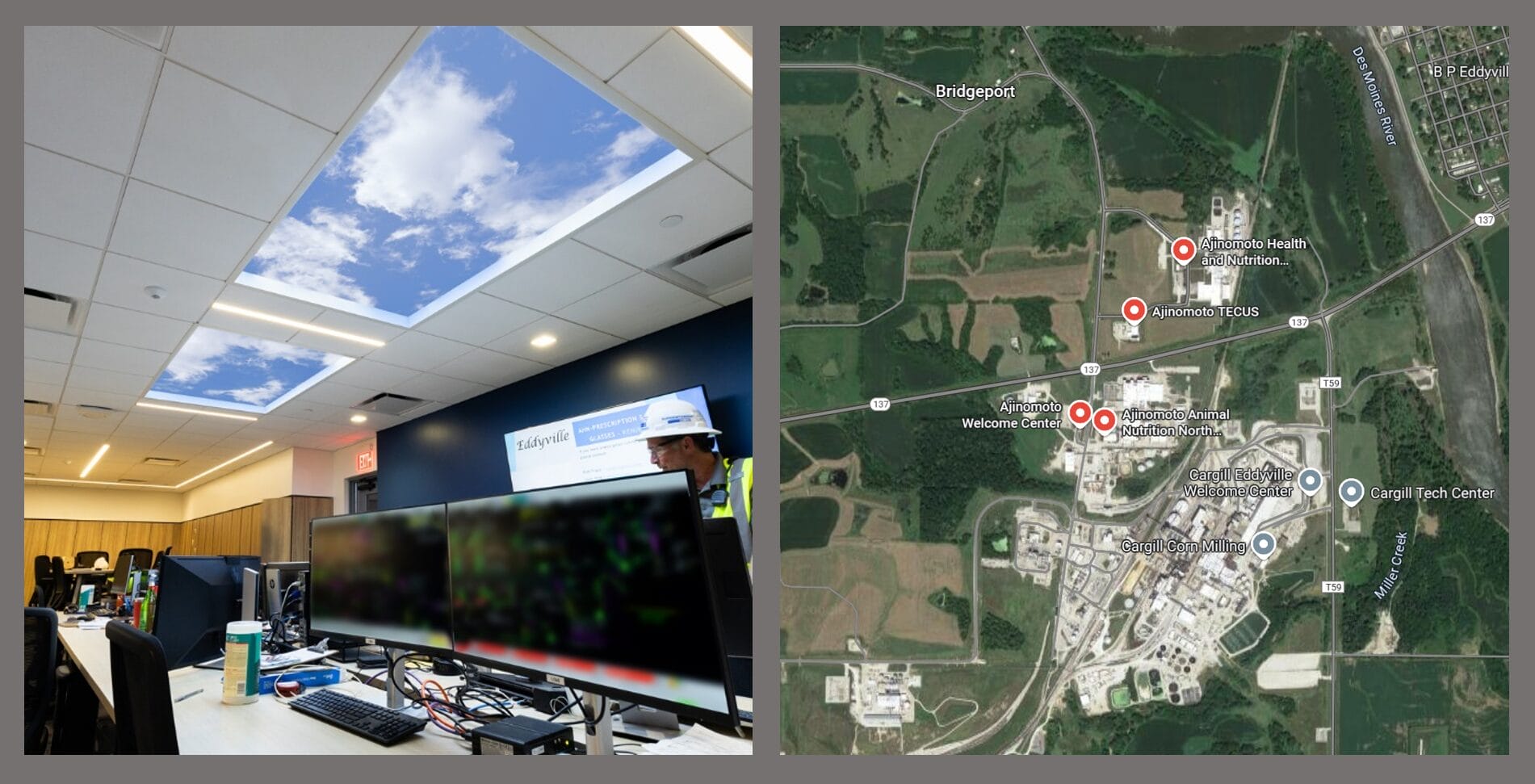

So what could Ajinomoto Heartland, one of the largest fermentation manufacturers in the world, offer its Eddyville, Iowa-based workforce to make the job sustainable? They designed several illusory portals of peaceful overhead skies to open up their isolated office spaces.

The company began taking a look at the heart of the plant—its control rooms and adjacent team meeting areas, which lay nestled inside a steel and aluminum fortress steaming with churning liquids and billowing gases from the manufacture of amino acids for use in animal feed supplements. Ajinomoto, a Japanese company, and one of the largest players in the global fermentation chemicals market, alone produces 25% of the world’s supply of lysine, an amino acid that’s a key component in protein synthesis.

In order to stay on top of the growing demand for lysine, the Eddyville facility rotates through three full-time shifts of personnel to keep the plant operational at all times. In 2023, the lysine market was valued at $8.6 billion dollars and is expected to grow by 7.2% CAGR (Compound Annual Growth Rate) from 2024 through 2033, placing a premium on production capacity and operating hours.

However, the toll on plant personnel is high. The workplace is loud, the high temperatures are grueling—ever so in the summers, and the control rooms are usually isolated, near the core of the plant, which can foster feelings of claustrophobia, raise cortisol levels, and exacerbate fatigue. The updated spaces feature new furnishings, dedicated HVAC equipment and controls, plus vibration-dampening to improve the comfort of employees using the space, said Sully Streeby, Carl A. Nelson & Company project superintendent.

All in all, Ajinomoto revamped two floors with control and conference rooms with a well-insulated interior envelope that would help the HVAC system keep the planning and monitoring spaces, cool. The commitment to a full renovation facilitated incorporating new amenities like staff lockers, a kitchenette area and virtual skylights in key rooms, added Streeby.

A Rare Look at Large Scale Fermentation Control Rooms

When clearance was finally granted to visit the Ajinomoto Heartland facility, our team set out to Eddyville, on a hot and humid summer day. Driving along US-34 West and US-63 North, on the way to Des Moines from southeast Iowa, we soon came upon an industrial park recognized by motorists for its steady stream of drifting white smoke.

The complex, part of a joint manufacturing operation spearheaded by Cargill, also harbors the lysine fermentation operations of Ajinomoto Heartland, Inc. On assignment to capture photography of Ajinomoto’s newly renovated conference rooms and operations control rooms, we figured the headquarters were located somewhere near the fermentation towers that dominate the Eddyville’s rural landscape.

However, much to our surprise, Sully drove straight into the plant complex until he parked at the foot of a six-story steel tower. The main bay revealed a deep maze of rising pumps, sprawling pipes, massive vats, and huge compressors whose cacophony can reach up to 85-100 decibels (dB) throughout the facility. As we ventured inside, ear plugs muffled the deafening noise, but not against the strong smells of what appeared to be a mix of ammonia, bleach, or manure.

We soon learned that even on a hot and humid summer day, it’s hotter inside the plant. Industrial fermentation processes require high temperatures, typically between 86-104oF (30-40oC), making the interior of large scale facilities like this one feel like a tropical jungle. After climbing the stairs to the fourth floor, dripping in sweat, our guide opened a large steel door and we stepped into one of the main control rooms.

The temperature instantly dropped by what felt like 35 degrees or more… A group of four shift workers, sprawled on assorted office chairs on rollers, barely glanced our way. Soaked in sweat they sat underneath of a pervasive and curiously calming blue hue underneath two skylights. Welcome to Control Room No. 1, now outfitted with a pair of 3-foot Aperture SkyCeilings (circular virtual skylights) overhead. As we cooled off, I began to appreciate what a credible view of open blue sky and clouds inside the core of the plant could do to make the cool air seem part of a much welcome oasis.

Here, the presence of a silent sky was certainly a sight for sore eyes. And that was precisely the relief Ajinomoto Heartland’s wanted to bring into the new control rooms where lysine production is monitored 24/7 on big monitors. Crews work along a chemist and engineers to gauge whether chemical catalysts cascade within their prescribed temperature range, that valves operate at the right pressure, and that all instruments are monitored to prevent disruptions or catastrophic malfunction.

Strict security and emergency protocols are followed or called upon according to the type of situation to insure that interruptions to the operation are kept at a minimum and maintenance is carried out as efficiently as possible to avoid production down time.

Fermentation Control Rooms & Biophilic Illusion of Nature

Carl A. Nelson Construction is a well-known quantity at Ajinomoto Heartland where it is responsible for assorted construction projects inside this shared industrial complex. Streeby, the project superintendent, noted the work was barely finished when the excited Ajinomoto team began occupying the renovated spaces.

Luminous SkyCeilings are the only virtual skylight with published research noting their ability to open up enclosed interiors, leading occupants to feel more relaxed and be able to recharge focused attention. In high pressure environments, research studies have found that a visual connection to wide open space like an overhead view of the sky, is linked to lower blood pressure and heart rate, improved mental engagement and attentiveness, as well as higher levels of job satisfaction.

Sky Factory is the only designer of evidence-based, virtual skylights that also provides continuing education courses on the benefits of biophilic design. Our family of Luminous SkyCeilings, Windows, and Digital Cinema applications are biophilic designed products that provide research-verified, architectural solutions for a range of healthcare and commercial spaces. To find out how Sky Factory can bring the healing presence of nature to your organization, contact us today.